charpy impact test common reference value|charpy impact test specimen size : agencies In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. WEBGanhe 100% em seu Depósito. Baixar Para Android. Baixar Para iOS. A Sapphirbet é uma das principais plataformas de jogos de azar e apostas esportivas do Brasil, oferecendo .

{plog:ftitle_list}

Para usar a ferramenta de criação de mídia, acesse a Página Download de Software da Microsoft do Windows 10 em um dispositivo Windows 7, Windows 8.1 ou Windows 10. Você pode usar essa página para baixar uma imagem de disco (arquivo ISO) que pode ser usada para instalar ou reinstalar o Windows 10. A imagem também pode ser usada para .

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The most common method is the notched-bar impact test for which two types of specimens prevail, Charpy and Izod. By subjecting a specimen to an impact load, it will fail if the load .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's . Principle of Charpy machine verification: if the impact test results (average value) from an industrial machine agree with the reference absorbed energy value established at .Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test .

charpy test sample dimensions

The absorbed energy of a test material, measured using a Charpy impact machine, is often reported as the mean absorbed energy of a set of specimens. However, the sample mean .The four most common impact-test procedures in use around the world are probably ISO 148 “Steel— Charpy impact test V-notch ,” ASTM E 23 “Standard Test Methods for Notched Bar .the production of reference Charpy specimens for the indirect verification of impact testing machines in accordance with ASTM E23-12c: two quenched and tempered 4340 steels (with different mechanical properties induced by different thermal treatments) and a T200 18Ni maraging steel. are defined in ASTM E23 as reference Charpy impact machinesfor . Principle of Charpy machine verification: if the impact test results (average value) from an industrial machine agree with the reference absorbed energy value established at NIST within the larger of 1.4 J or 5 %, the machine is certified in accordance with ASTM E23. .

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the .

An Izod impact testing apparatus — which is essentially identical to a Charpy impact testing machine — is used to determine Izod impact strength. The primary differences between the Izod and Charpy impact tests are the size of the test specimen, how it is restrained, and which side is struck by the pendulum hammer. . Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead .Explore the Charpy impact test method for metallic materials as specified by the European EN 10045 standard. Understand the test's purpose, procedure, and the significance of the energy absorbed in joules. . Reference (Figure 1) Designation: Unit: 1 : Length of test piece : mm : 2 : Height of test piece : mm : 3 : Width of test piece : mm : 4 . The NIST Charpy Machine Verification Program is introducing certified low-energy and high-energy Charpy specimens to be tested at 21 °C instead of -40 °C.These new Standard Reference Materials can be ordered from the NIST SRM store (https://shop.nist.gov/) using the following numbers:Low-energy: SRM 2561 (NIST-Verification, 21 °C, 8 mm strikers),

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .Charpy impact is a standardized high strain rate test to measure energy absorption during fracture. The absorbed energy provides an indirect measure of fracture toughness. Despite its relative ease of use, complex energy loss mechanisms are involved, making it impossible to verify test machine performance directly. Periodic testing of impact .

An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a . A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. . NIST certifies its reference specimens using three of the Boulder lab’s multiple Charpy machines, and ships out about . The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a .

CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values recorded can be used for qualitya) Notched and Unnotched Charpy Test; b) Notched and Unnotched Izod Test (Source: ScienceDirect) These tests can be used as a quick and easy quality control check. They determine if a material meets specific impact properties .A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation .

Both methods characterize the impact strength of a material in very similar ways so that the results largely correlate. The Izod test method, in which the specimen is positioned vertically, is normally used in ASTM standards.; The Charpy .1.1 - Pendulum Impact Test The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is expressed in term of kinetic energy consumed by the pendulum in order to break the specimen. The energyThree Charpy machines located at NIST in Boulder, Colorado, are used to qualify verification specimens and produce certified values of absorbed energy (KV). These machines are indicated as “reference machines” in ASTM E23-16b. Every year, the Charpy program at NIST evaluates the indirect verification results of more than 1500

The result of this work is NextGen’s line of impact test equipment, which includes combined systems covering the entire range of impact test energies: Class J – Charpy and Izod Automatic Impact Testing System – 1J – 50J; Class D – Dual Column Charpy Impact Tester – 150J, 300J, 450J, 600J or 750J.

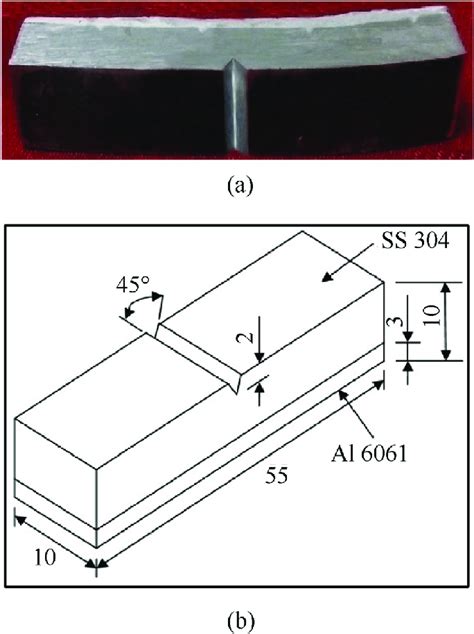

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a). Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015). History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .The Charpy-V test for characterising notch toughness is described. The qualitative nature of the test, outline procedures and test analysis are described. . rather than specifying an impact value. Fig.4 Lateral expansion. The next article in this series will look at the testing of welds, how the impact strength can be affected by composition .

Abstract. The Charpy V-notch (CVN) impact test has been widely used by operators and pipe mills to measure steel pipe resistance to fracture propagation. The tests are generally conducted at multiple temperatures to capture the transition from low impact energy nonductile regime to the high impact energy ductile regime. Due to the limitation of wall .The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . The pointer is set up to its maximum value(300 J). The hammer is released from the initial height downward towards the sample.

Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material.

charpy impact test standard pdf

charpy impact test specimen size

compression tester adapter ih d236 d282

WEB4 de dez. de 2023 · Leia o capítulo Damn Reincarnation Capítulo 76 em Mangás Online . O mangá Damn Reincarnation é sempre atualizado em Mangás Online . Não se .

charpy impact test common reference value|charpy impact test specimen size